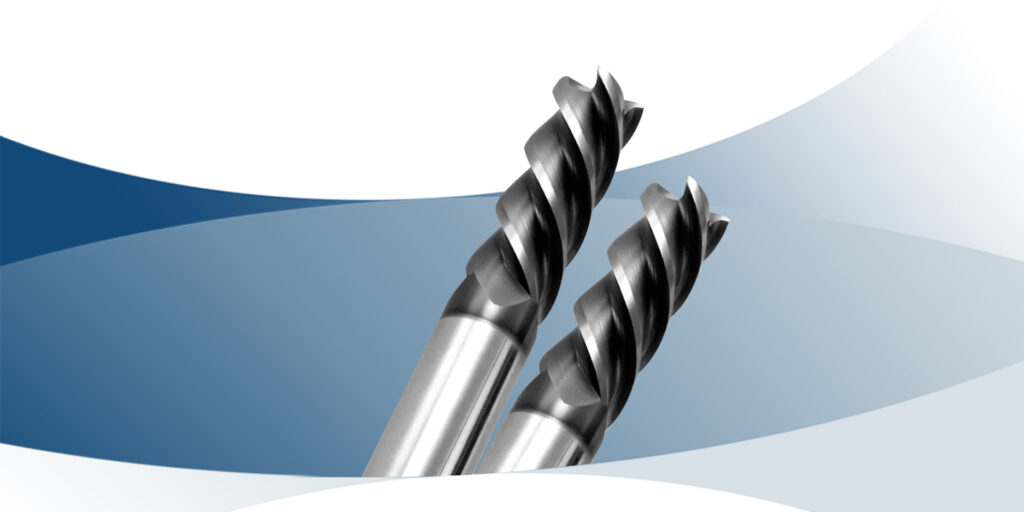

The remarkable world of crafting and manufacturing is filled with fascinating tools, and one that stands out is the carbide end mill. This part may seem less glamorous than large machinery, but its advantages and areas of application are truly impressive, and make it a vital component in an array of sectors.

As the name suggests, a carbide end mill is a type of cutting tool typically used in industrial milling applications. One of its most notable advantages is the use of carbide, a super-strong material that offers excellent hardness and heat resistance. This makes carbide end mills highly durable and long-lasting, even in high-speed cutting operations.

Imagine you’re manufacturing a piece of intricate jewellery or a precision-engineered automobile part. A carbide end mill, with its superior hardness, can maintain a sharp cutting edge for longer periods of high-speed operation on surfaces like aluminium, steel, or copper, compared to other types of cutting tools. This means reduced downtime for tool changeovers, leading to increased productivity – a significant advantage for customers.

Another critical advantage of a carbide end mill lies in the precision it provides. Picture yourself engaging in a woodworking hobby, creating a beautiful wood sculpture. The smooth and precise cuts a carbide end mill can make will bring out the details of your design effortlessly, offering a clear edge over other types of cutting tools.

But how do we properly utilize this wonderful tool? The key to harnessing the full potential of a carbide end mill lies in understanding and maintaining its cutting parameters. These parameters include the speed at which you move the tool, the rate at which material is fed into the tool, and the depth of the cut. Operating within these parameters ensures the best performance and longevity of the tool.

Let’s say you’re using a carbide end mill to create intricate designs on a block of aluminium. If you move the tool too fast or feed in material too quickly, the end mill might overheat, leading to premature wear. Alternatively, if your depth of cut is too heavy, it could lead to tool breakage. Understanding these parameters helps to avoid unsatisfactory results, and increases the life span of the carbide end mill.

The carbide end mill, with its versatility, durability, and precision, truly shines in applications ranging from jewellery making, automobile part production, woodworking, and more.

In conclusion, the carbide end mill is a powerful tool that offers numerous advantages, from its exceptional performance in high-speed cutting operations to the precise and smooth cuts it can deliver. Understanding its cutting parameters can greatly enhance its utility and lifespan. The carbide end mill, a seemingly small tool, holds an indispensable role in the creation of the world’s goods, from the tiniest piece of jewellery to the largest of automobiles.