In the world of machining stainless steel, finding the right end mill can make all the difference. With so many options available, it can be overwhelming to determine which one is the best fit for your specific needs. In this article, we will explore the key factors to consider when choosing a 2 flutes end mill for stainless steel machining.

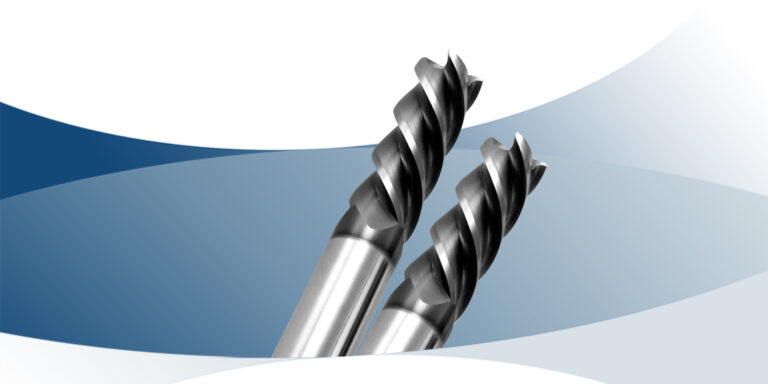

First and foremost, it’s essential to understand the importance of the number of flutes in an end mill. Flutes are the cutting edges on the end mill, and the number of flutes directly affects the performance. A 2 flutes end mill is a popular choice for stainless steel machining due to its balance between chip clearance and strength. It allows for efficient chip evacuation while maintaining stability during the machining process.

Additionally, the material and coating of the end mill play a significant role in its performance. Stainless steel is a notoriously challenging material to machine, as it is prone to work hardening and has a high thermal conductivity. Therefore, it’s crucial to choose an end mill made from high-quality carbide, which offers excellent wear resistance and heat resistance. Furthermore, opting for an end mill with a high-performance coating, such as TiAlN or TiSiN, can further enhance its durability.

When selecting a 2 flutes end mill, considering the helix angle is also crucial. The helix angle determines the amount of cutting forces generated during the machining operation. In stainless steel machining, a higher helix angle, around 45 degrees, is recommended. This angle helps reduce cutting forces, extending tool life and improving surface finish.

Another important factor to consider is the diameter of the end mill. The diameter determines the amount of material that can be removed in each pass. For stainless steel machining, a smaller diameter end mill is typically preferred, as it provides higher rigidity and enables deeper cuts. However, it is important to strike the right balance between diameter and cutting speed, as too small of a diameter can result in reduced feed rates and prolonged machining times.

Now, let’s delve into some specific examples to illustrate the versatility and advantages of a 2 flutes end mill for stainless steel machining. Imagine you are manufacturing aerospace components from stainless steel. These complex parts require precise machining to meet stringent quality requirements. By using a 2 flutes end mill with a high helix angle, you can achieve exceptional surface finishes and reduce the risk of workpiece distortion. Additionally, the efficient chip evacuation provided by the 2 flutes design ensures excellent productivity and prolongs tool life.

In the automotive industry, stainless steel is often used in the production of engine components. Here, the challenge lies in machining tough materials while maintaining tight tolerances. By selecting a 2 flutes end mill with a smaller diameter, you can effectively remove material, even in hard-to-reach areas. The balanced design of the 2 flutes end mill allows for smooth cutting action, reducing vibrations and ensuring consistent performance.

In conclusion, choosing the best 2 flutes end mill for stainless steel machining requires careful consideration of several key factors. By selecting an end mill with the right number of flutes, material and coating, helix angle, and diameter, you can optimize performance, improve productivity, and achieve exceptional results. Remember, stainless steel machining can be challenging, but with the right tools, you can overcome any obstacles and achieve success.