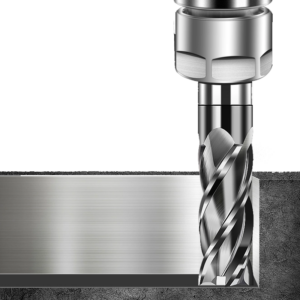

Custom end mills have become an indispensable tool in the world of milling operations. These cutting-edge tools not only enhance the efficiency of the milling process but also provide numerous advantages to businesses seeking precision and reliability. In this article, we will delve into the various ways in which custom end mills can transform your milling operations, leaving you with remarkable results and an edge over your competitors.

One of the most significant advantages of custom end mills is their ability to be tailored precisely to meet the unique requirements of each milling operation. Unlike standard end mills that offer limited options, custom end mills can be designed to fit the specific needs of your project. This customization allows for optimum performance in terms of speed, accuracy, and durability. For instance, if you require milling through challenging materials like hardened steel or titanium alloys, your custom end mill can be designed with appropriate coatings and geometries to ensure efficient material removal without compromising on quality.

Moreover, custom end mills offer improved tool life, which translates to substantial cost savings in the long run. These tools are engineered with cutting-edge materials and coatings that enhance their wear resistance and reduce friction during the milling process. As a result, they can withstand high cutting speeds and prolonged use without succumbing to wear and tear. By investing in custom end mills, you can avoid frequent tool replacements and significantly enhance your production output and profitability.

Custom end mills also contribute to increased efficiency and productivity. Their tailor-made design enables them to optimize chip evacuation, preventing chip clogging and minimizing downtime for tool cleaning. This superior chip evacuation capability translates to uninterrupted milling operations, resulting in higher throughput and reduced production time. Furthermore, by utilizing custom end mills with advanced geometries and high-performance coatings, you can achieve higher cutting speeds and feed rates, boosting your productivity exponentially.

The versatility of custom end mills extends beyond a single application. These tools find their application in a wide range of industries, including aerospace, automotive, medical, and mold and die. Their adaptability to various materials and cutting conditions makes them a go-to choice for professionals in these industries. For example, aerospace manufacturers rely on custom end mills to precisely cut intricate shapes and contours in aircraft structural components. Similarly, the medical industry utilizes custom end mills to manufacture precision medical devices, ensuring impeccable quality and performance.

Furthermore, custom end mills provide flexibility and innovation to milling operations. Manufacturers can experiment with different tool geometries, coatings, and cutting parameters to optimize their milling processes and achieve unparalleled results. As businesses strive for continuous improvement and stay ahead of the competition, custom end mills enable them to push boundaries and explore new avenues of efficiency and innovation.

Custom end mills revolutionize milling operations by offering tailored solutions, cost-effective tool life, increased efficiency and productivity, versatile applications, and flexibility for continuous improvement. By capitalizing on the advantages of custom end mills, businesses can optimize their milling processes and achieve exceptional results. So why settle for standard tools when you can unlock the full potential of your milling operations with custom end mills? Upgrade your milling capabilities today and experience the difference firsthand.