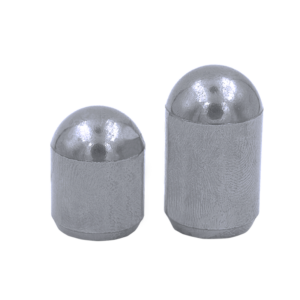

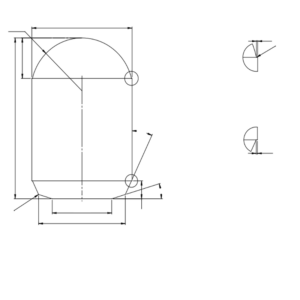

球齿

我们的硬质合金采矿零件包括专为采矿和钻井应用而设计的各种球齿。这些球齿是钻头、潜孔锤和道路铣刨工具等钻孔工具构造中使用的重要组件。我们的硬质合金球齿以其卓越的硬度、耐磨性和韧性而闻名,在要求苛刻的采矿作业中提供卓越的性能和耐用性。

Process Flow

Ball milling process

Our company’s tungsten carbide and cobalt powders are all selected from the best raw material manufacturers. During the process, different proportions of raw materials and paraffin forming agent are added into the ball mill at the same time with alloy balls. Under the impact and grinding action between the raw materials and the alloy balls, the raw materials of each component are refined and evenly distributed with the addition of alcohol grinding medium.

Spray drying process

After unloading, spray drying and solid-liquid separation are carried out to make a paraffin mixture with specific composition and particle size requirements,to prepare for the following pressing and vacuum sintering.

Pressing

The prepared paraffin mixture is determined as qualified mixture based on inspections from our testing center. Load the mixture into the molding cavity, under the pressure of the punch, the pressure is transferred to the powder in the cavity, with the impact of the forming agent, the final mixture is compacted into a blank with a certain shape, size, density, strength and no defects.

In order to obtain high-precision blanks, our company has two-way presses, Oswalder presses and dry bag presses.

Throughout the production process, we will conduct the first inspection, process inspection, and final inspection of the product during the production process. The testing center will conduct the first inspection, process inspection, and final inspection of the blanks to monitor the entire production process.

HIP sintering

Our company is equipped with 10mpa, 6mpa and various other low-pressure sintering furnaces.

Our sintered products are obtained through four continuous processes:

1. low-temperature dewaxing

2. high-vacuum and high-temperature sintering

3. cooling

4. unloading.

The entire process has a complete numerical display to facilitate the process control machine to observe problems.

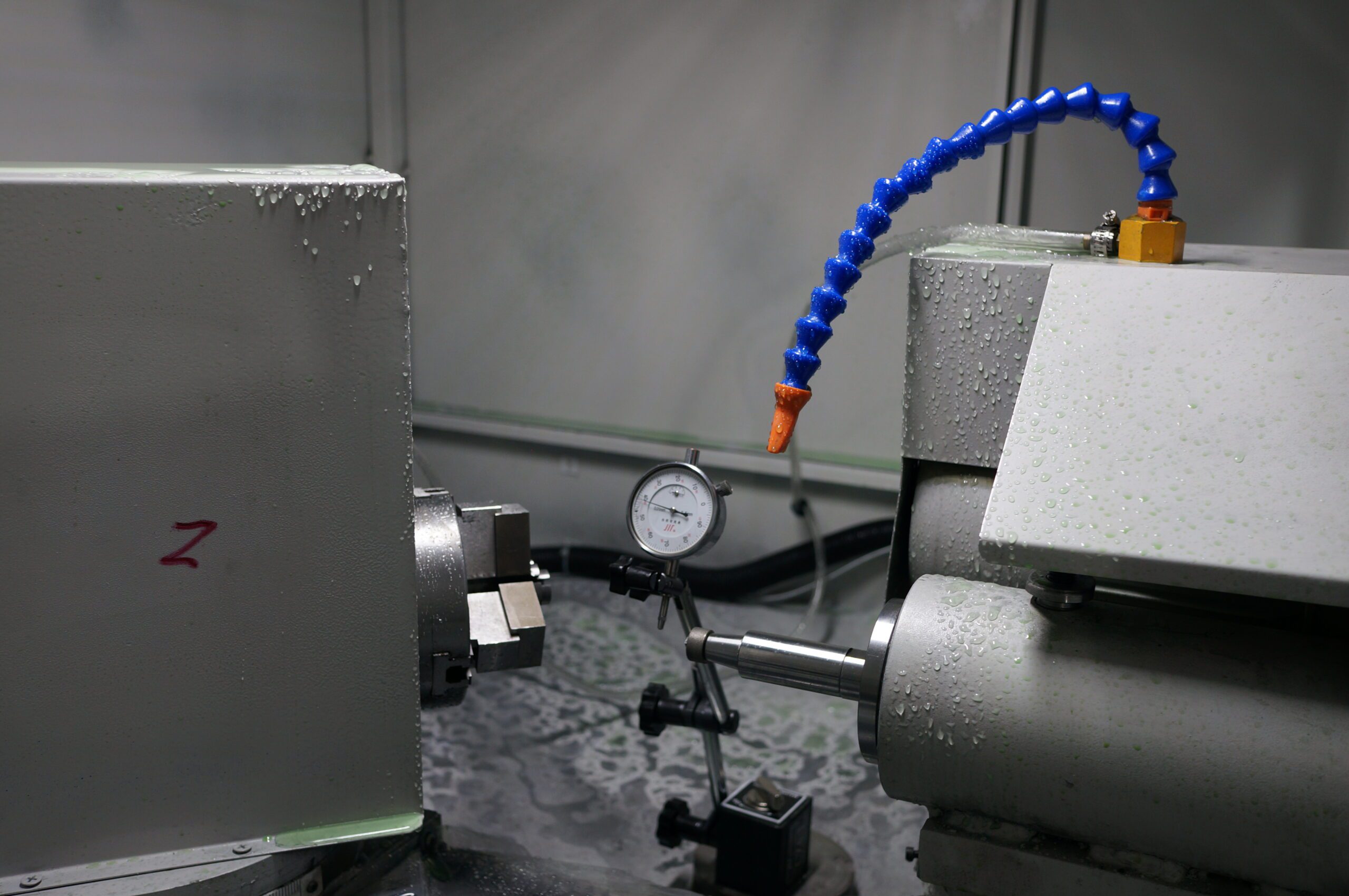

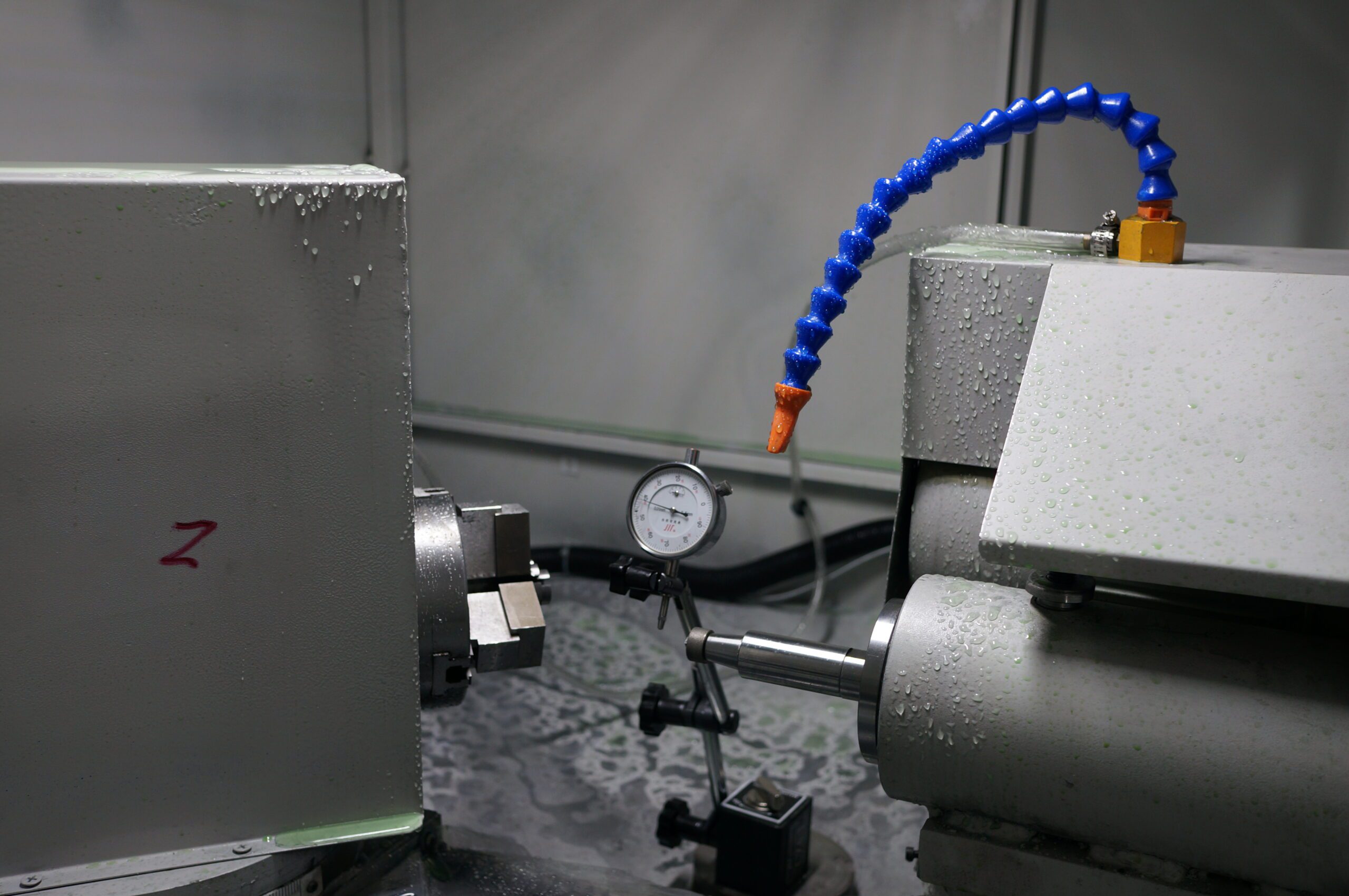

Grinding

Our company uses a large number of CNC machines. The grinding process ensures product consistency and can achieve one operator can operate multiple grinders because it is fully automatic, which reduces the requirements for personnel and saves energy consumption at the same time. During the processing, the operators are required to proceed initial-inspection, operator-inspection, and process inspection of all products. The testing center will review the self-inspection, and also have auditor-inspections, patrol inspections (routing inspection, procedure), process inspections and full inspections of the final product.

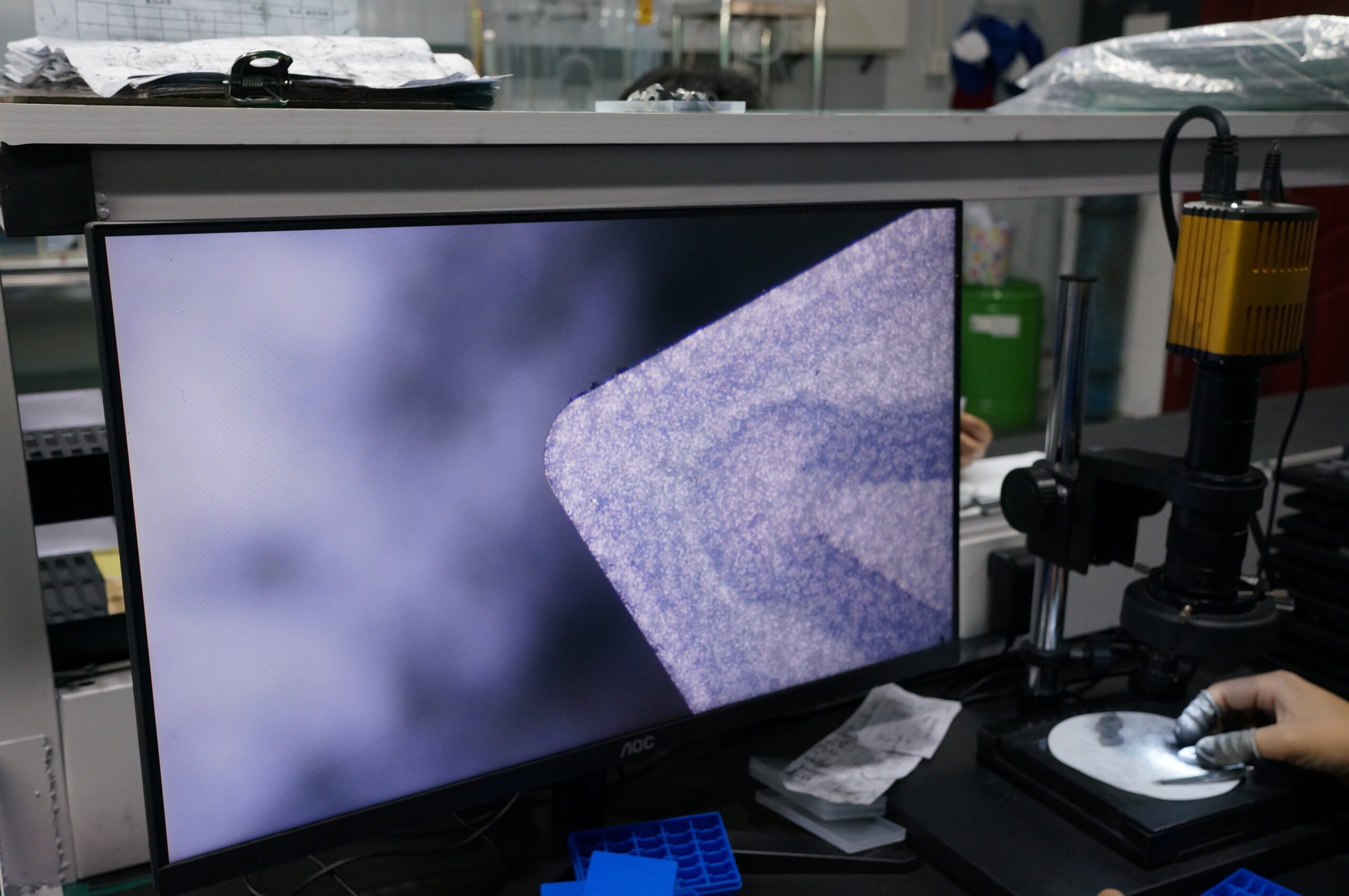

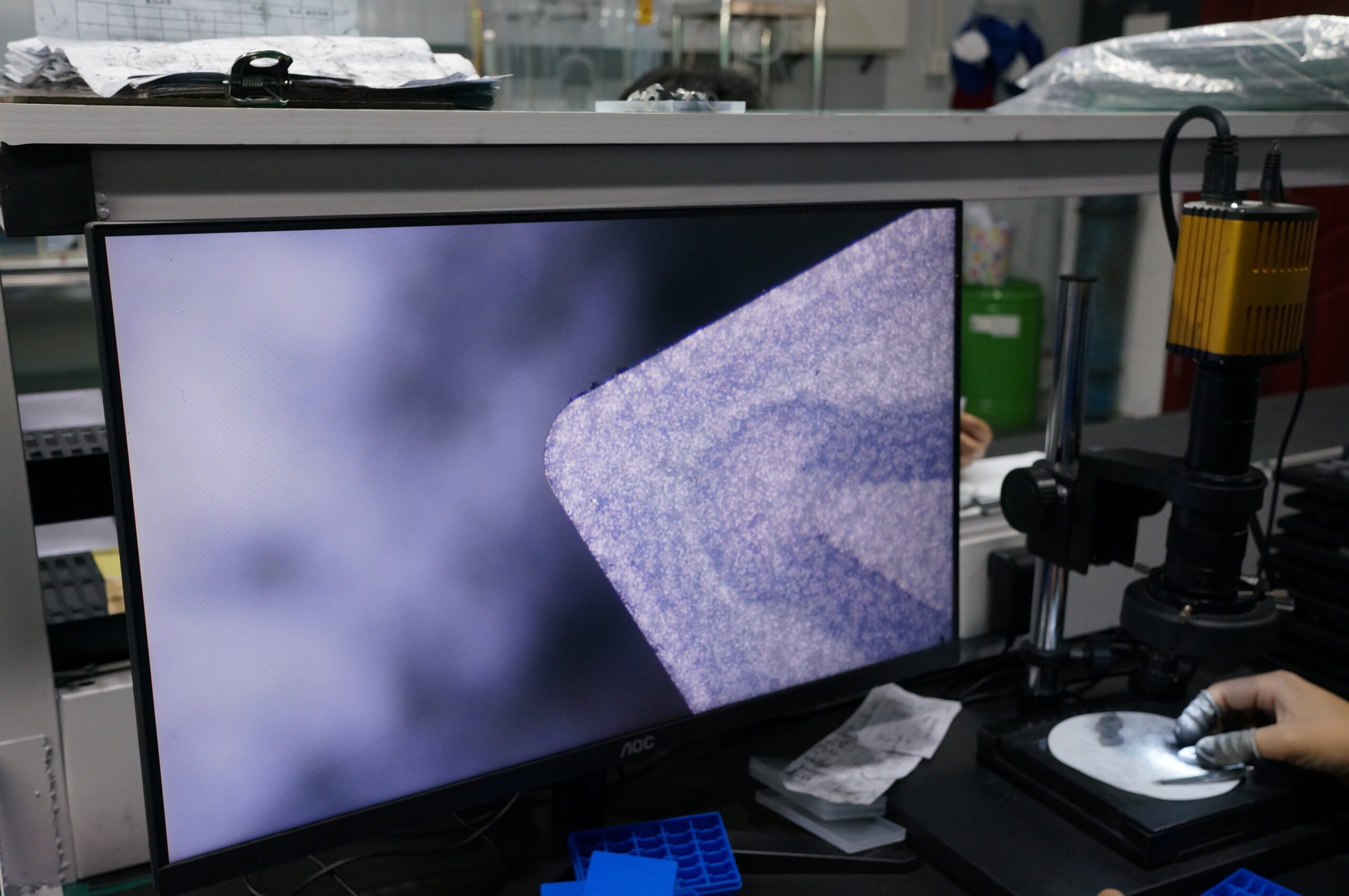

Testing

In order to meet a higher expectations of our customers, in addition to the conventional physical performance testing equipment, we are also equipped with Alicona 3D profile measuring instrument, which can achieve measurements of complex surfaces of high-precision parts.

In the measurement process, high-speed, high-precision, high-repeatability, and large-area integrated measurement can be realized at the same time.

Spray drying process

After unloading, spray drying and solid-liquid separation are carried out to make a paraffin mixture with specific composition and particle size requirements,to prepare for the following pressing and vacuum sintering.

HIP sintering

Our company is equipped with 10mpa, 6mpa and various other low-pressure sintering furnaces.

Our sintered products are obtained through four continuous processes:

1. low-temperature dewaxing

2. high-vacuum and high-temperature sintering

3. cooling

4. unloading.

The entire process has a complete numerical display to facilitate the process control machine to observe problems.

检测

In order to meet a higher expectations of our customers, in addition to the conventional physical performance testing equipment, we are also equipped with Alicona 3D profile measuring instrument, which can achieve measurements of complex surfaces of high-precision parts.

In the measurement process, high-speed, high-precision, high-repeatability, and large-area integrated measurement can be realized at the same time.

Ball milling process

Our company’s tungsten carbide and cobalt powders are all selected from the best raw material manufacturers. During the process, different proportions of raw materials and paraffin forming agent are added into the ball mill at the same time with alloy balls. Under the impact and grinding action between the raw materials and the alloy balls, the raw materials of each component are refined and evenly distributed with the addition of alcohol grinding medium.

压制

The prepared paraffin mixture is determined as qualified mixture based on inspections from our testing center. Load the mixture into the molding cavity, under the pressure of the punch, the pressure is transferred to the powder in the cavity, with the impact of the forming agent, the final mixture is compacted into a blank with a certain shape, size, density, strength and no defects.

In order to obtain high-precision blanks, our company has two-way presses, Oswalder presses and dry bag presses.

Throughout the production process, we will conduct the first inspection, process inspection, and final inspection of the product during the production process. The testing center will conduct the first inspection, process inspection, and final inspection of the blanks to monitor the entire production process.

Grinding

Our company uses a large number of CNC machines. The grinding process ensures product consistency and can achieve one operator can operate multiple grinders because it is fully automatic, which reduces the requirements for personnel and saves energy consumption at the same time. During the processing, the operators are required to proceed initial-inspection, operator-inspection, and process inspection of all products. The testing center will review the self-inspection, and also have auditor-inspections, patrol inspections (routing inspection, procedure), process inspections and full inspections of the final product.