What is an end mill| Cnclathing

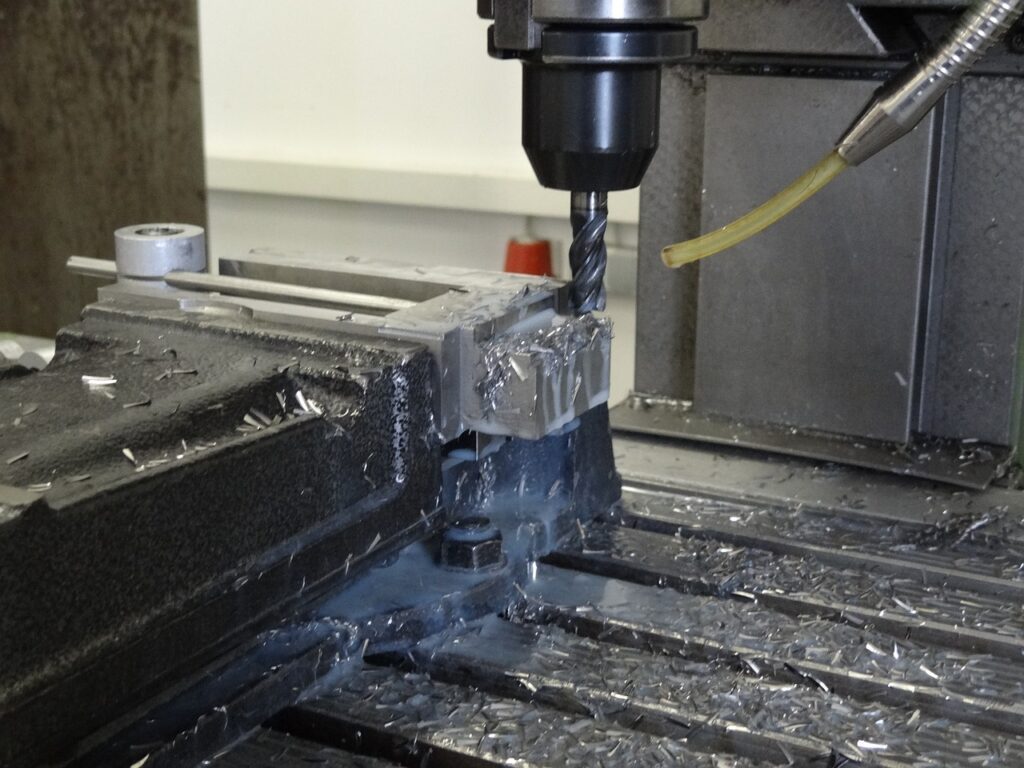

Highly automated milling is a versatile machining process capable of producing components of almost any shape. There is a wide variety of CNC milling operations employed for different manufacturing purposes. End mills differ primarily from other machining because they are the type of tool used to cut materials. In this article, we will outline the types of end mills, what an end mill is and find out the difference between an end mill and a drill.

What is end milling?

End milling is a milling process that can be used to produce slots, shoulders, mold cavities, contours, profiles and other milled parts. End milling uses an end mill, which is a cylindrical tool with multiple cutting edges on its perimeter and its tip, allowing end cuts and peripheral cuts.

What is an end mill?

An end mill is a milling cutter that cuts axially and is suitable for end mills, profile mills, tracer mills, face mills and straight insert mills. End mills and other cutting tools can be made from a variety of materials such as carbide inserts (for high production milling), high speed steel (when a special tool shape is required), ceramic inserts (for high speed high volume machining) and diamond inserts (to provide close tolerances). High-speed steel (HSS) and tungsten carbide are the two most common materials used to manufacture end mills. End mills allow for precision cutting to manufacture milled parts for a wide range of applications including jewelry, sign making, mold making, circuit boards, wood carving, machine parts, and more. End mills come in different lengths, diameters, grooves and types.

Common types of end mills

End mills can be classified according to flute, helix angle, shape, material, coating, etc. Here, we talk about some common end mills.

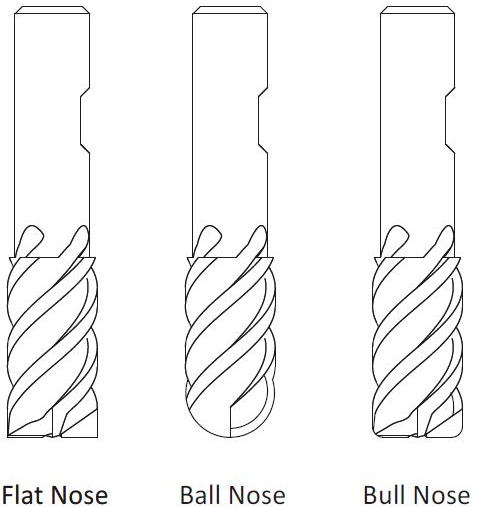

1.Different shapes of end mills

-Ball nose end mill:Has a radius at the bottom to give a greater surface finish, produces a round hole pattern, suitable for 3D contouring, shallow grooves, pockets and contouring applications.

- v-bit:Has a small angle and tip that produces a v-shaped channel for engraving, narrow cuts, small but delicate engraving and lines, especially for making signs, it can also be used for unusually sharp edges. v-bit end mills come in two forms:60° v-bit and 90° v-bit.

- Fishtail End Mills: With a thinner cutting edge at one end than the other, fishtail end mills allow direct access to the material and produce a flat surface, preventing any chips or breakthroughs, producing clean edges on thin materials making pockets with flat bottoms, suitable for plunging and producing precise contours such as signs. With a fishtail mill, you can also have nice square corners on the bottom of any illustrated part of the geometry.

- Square End Mills: Also known as flat end mills, they are general purpose mills that produce flat 50° angles in the workpiece and involve milling operations such as side milling, face milling, etc. Square ends can be used in the roughing or finishing stages.

- Bullnose tool end mills: Also known as corner radius end mills, this type of tool is a combination of a fishtail and a ball nose, also with a flat base but rounded corners. Bullnose end mills are usually used for grinding molds (injection molds, die casting molds, etc.)

- End mills with different number of slots

The spiral cutting teeth on the end mill are flutes to provide an empty path for cutting chip removal during machining. Available in 2,3 or 4 flutes, 2 and 4 flute end mills are more commonly available for end mills. More flutes will produce a smoother surface finish with less debris, optimal chip removal, and maintain heat build.

- 2 Flute End Mills: Suitable for working with wood and aluminum because they produce large chips

- 4 Flute End Mills: Used for machines with the most other materials that are more difficult to cut than 2 flutes

- End Mills of different materials

-High Speed Steel (HSS): cheaper than carbide tools, but also faster

- Carbide: fragile, can be crushed, provides better wear resistance and toughness. Carbide end mills are very heat resistant and are used for high speed applications on some of the hardest materials.

- Carbide resistant end mills: harder than other types, wear resistant, more wear resistant

Endcaps are also available with different coatings and helix angles.

Difference between End Mills and Drills – Drills and End Mills

An end mill is similar to a drill in appearance, what is the difference between an end mill and a drill, drill vs end mill and when to use an end mill?

- Rotary end mills can cut sideways or horizontally, and many end mills can cut axially and laterally, while drills inserted directly into the material can only move up and down and cut vertically.

- End mills are general purpose milling cutters used to machine slots, contours, cavities, and more features, while drills are used to cut or produce round holes

- An end mill can also be used to machine holes, but it requires a hole that has already been drilled, and you can use a drill bit to machine the hole directly with the material.

The tip of the drill is usually tapered, the only exception is a diamond drill with a flat end, milling tools are available in a variety of shapes and sizes, a plain end mill with a flat tip, a nose and a ball end mill at the end of the cut with a summary file. You can choose the right end mill according to the material to be cut and the surface finish.